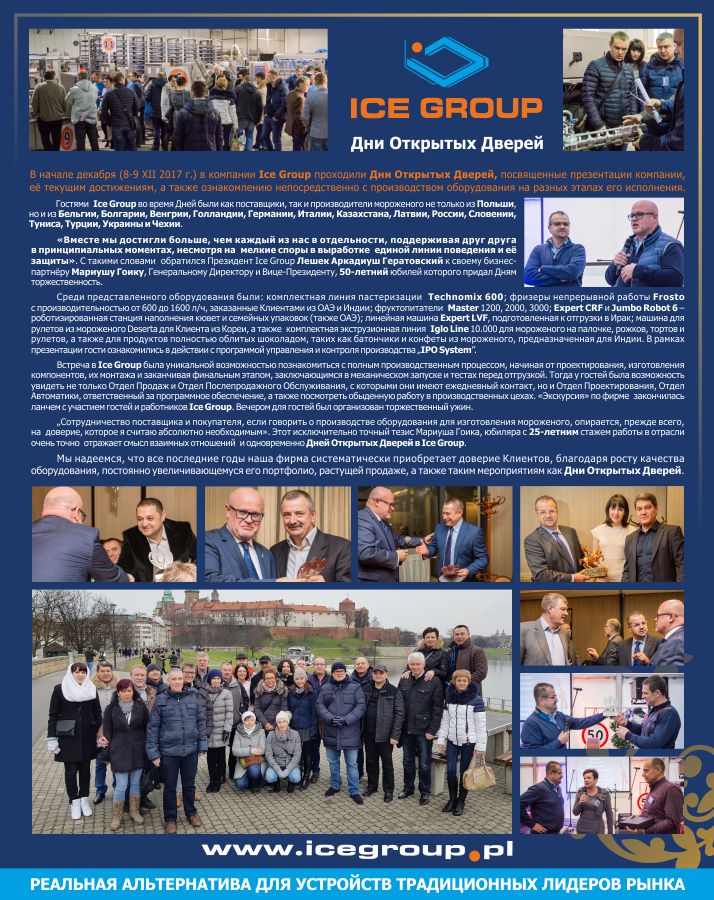

At the beginning of December (8-9 Dec 2017) Ice Group sp. z o.o. organized Open Days dedicated to the presentation of the company, its current achievements and showing machines at different stages of production right at the company seat.

The guests of Ice Group during the Open Days included both suppliers and ice cream producers, not only from Poland, but also from Belgium, Bulgaria, Czech Republic, Germany, Hungary, Italy, Kazakhstan, Latvia, the Netherlands, Russia, Slovenia, Tunisia, Turkey and the Ukraine.

At the beginning of December (8-9 Dec 2017) Ice Group sp. z o.o. organized Open Days dedicated to the presentation of the company, its current achievements and showing machines at different stages of production right at the company seat.

The guests of Ice Group during the Open Days included both suppliers and ice cream producers, not only from Poland, but also from Belgium, Bulgaria, Czech Republic, Germany, Hungary, Italy, Kazakhstan, Latvia, the Netherlands, Russia, Slovenia, Tunisia, Turkey and the Ukraine.

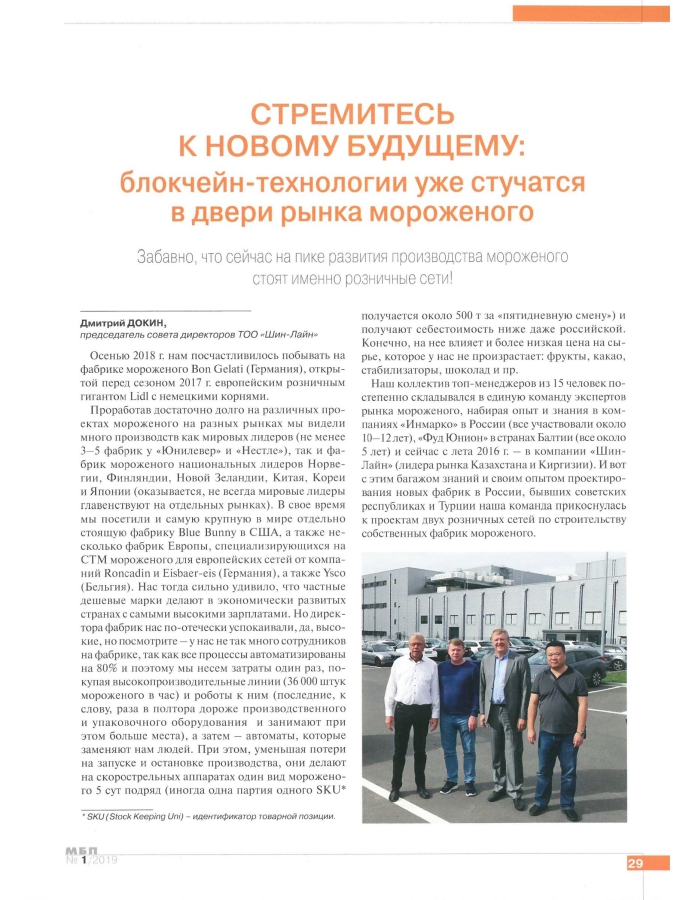

“Together we’ve achieved more than each of us ever before, supporting each other in crucial moments, despite partial disputes, to maintain a common, uniform course and defend it” – such were the words with which the President of the company, Leszek Arkadiusz Geratowski, addressed Mariusz Goik - the General Manager, vice-President and Co-owner, whose 50th birthday constituted yet another celebratory aspect of the Open Days.

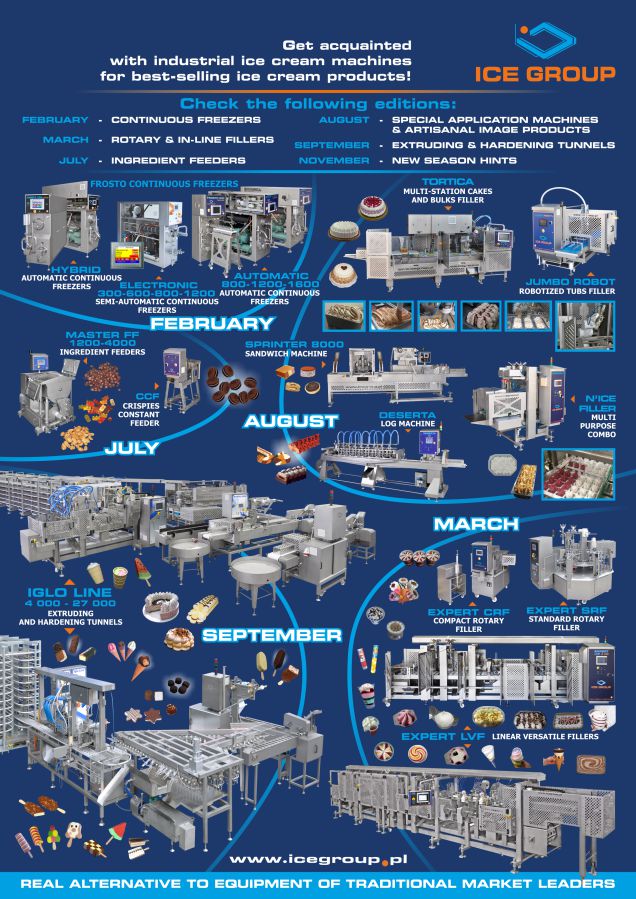

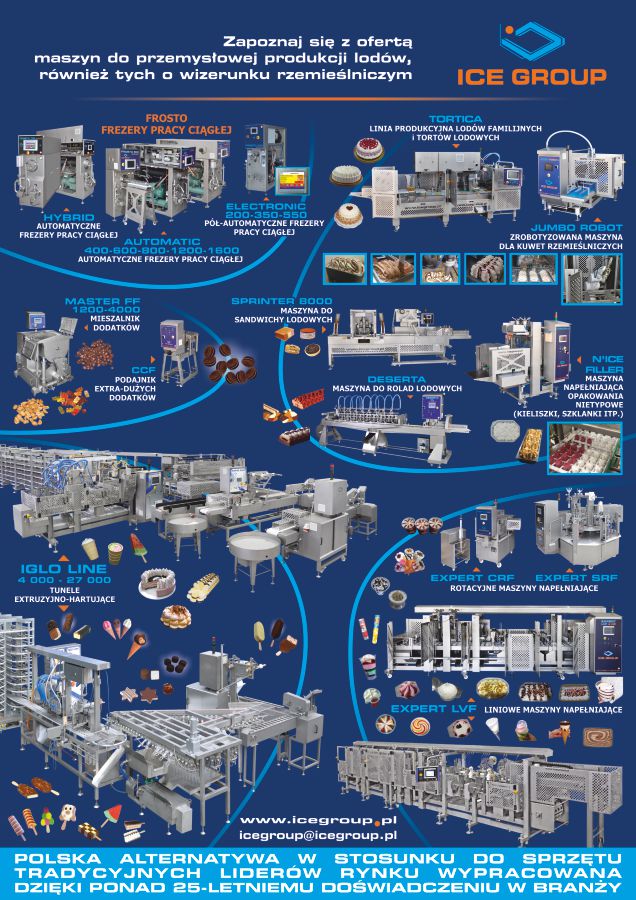

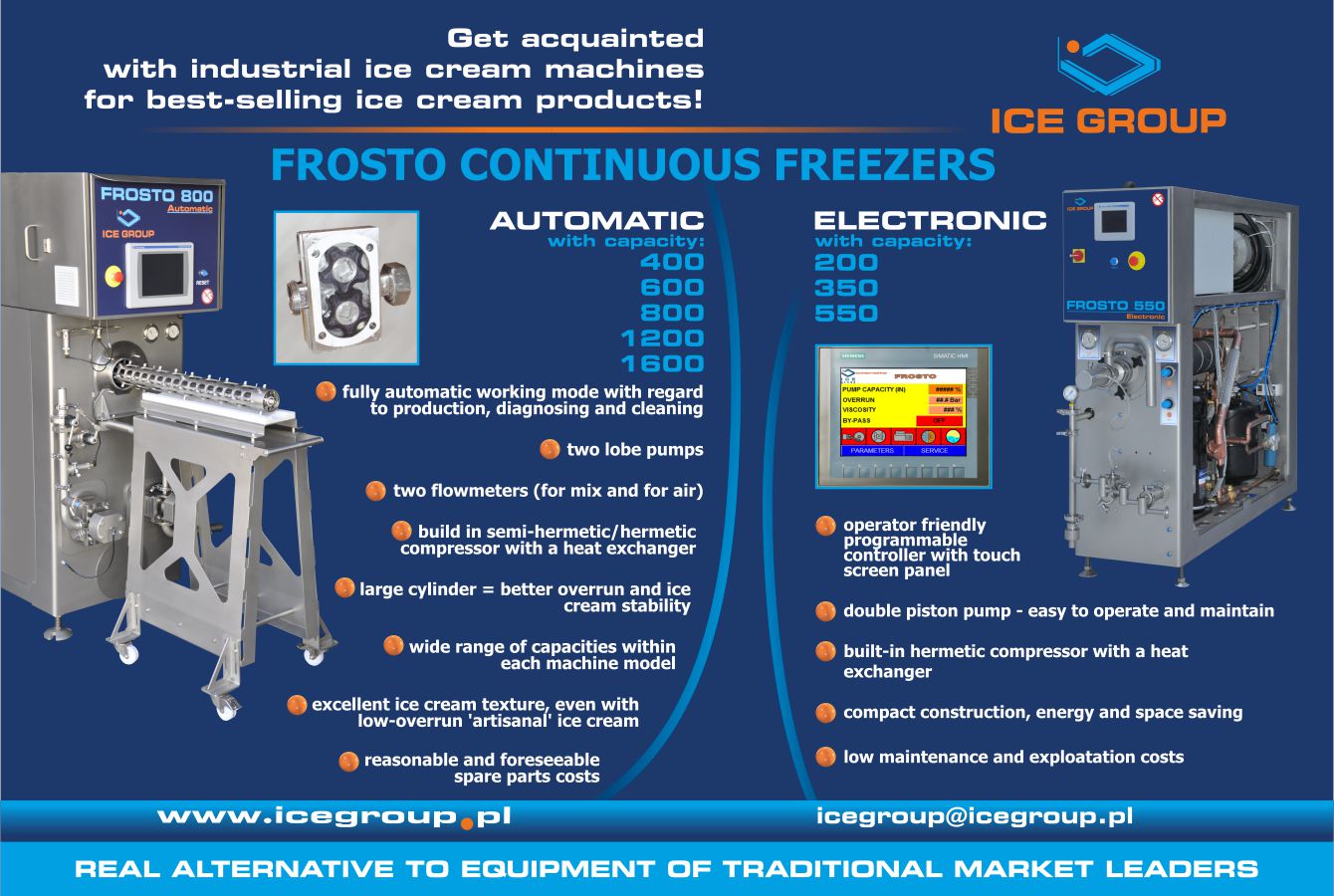

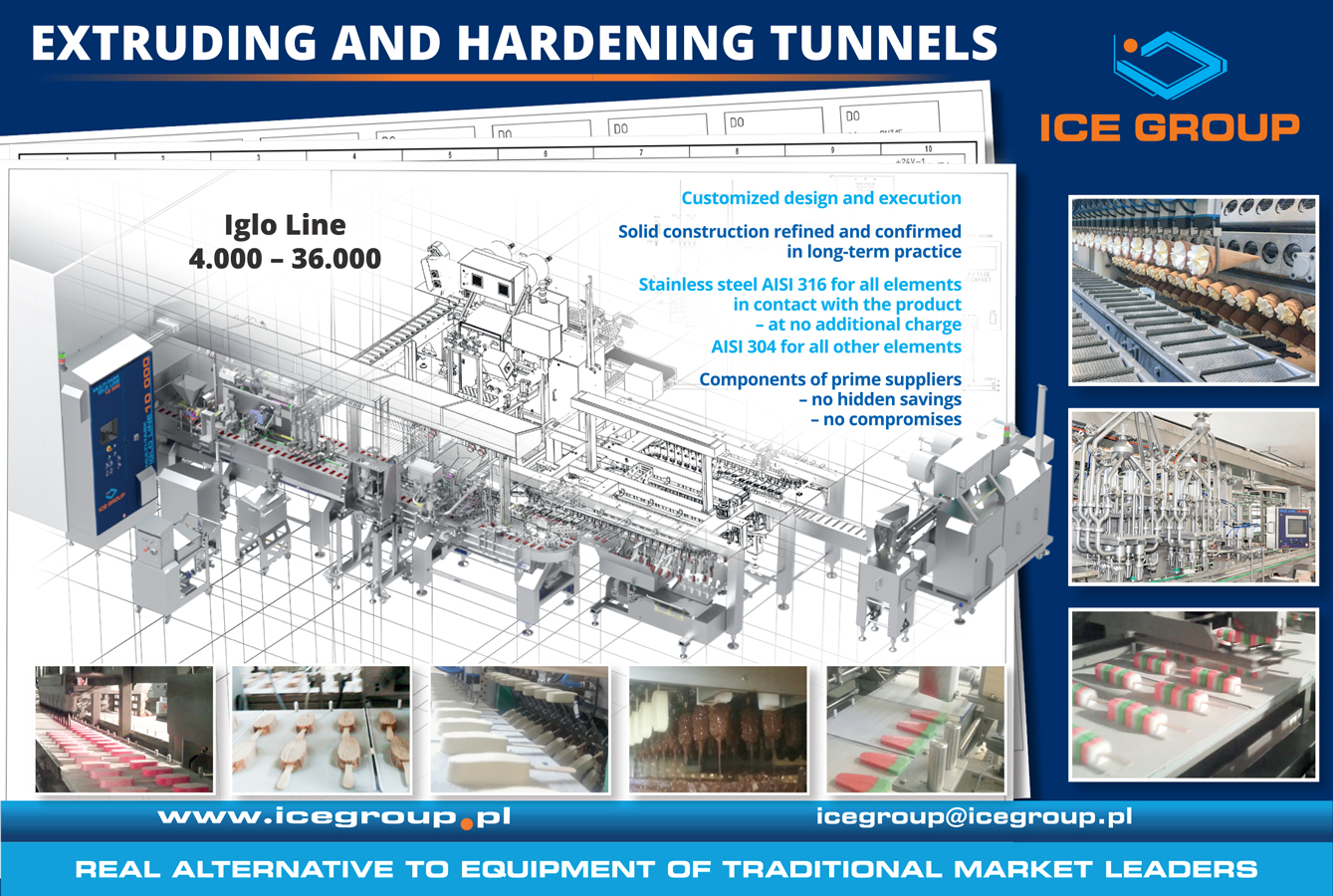

The machines presented during the event included, among others, a complete pasteurization line Technomix 600, continuous freezers Frosto of capacities ranging from 600 to 1600 l/h, ordered by Clients in the United Arab Emirates and India, Master FF fruit feeders 1200, 2000 and 3000, Expert CRF and Jumbo Robot 6 – a robotized filling station for scooping tubs and family containers, also for the Client in Emirates, in-line filler Expert LVF, prepared to be sent to a Client in Iraq, Deserta i.e. ice cream log machine for a Client in Korea and a complete 10.000 extrusion line for stick products, ice cream cones, cakes and logs, as well as products fully coated with chocolate, such as ice cream bars and bon-bon candies, made for the Client in India. As a part of company presentation, the guests also got acquainted with the production management and control program “IPO System” and its functioning in practice.

The meeting at Ice Group was a unique opportunity to see the full production process, starting from designing, production of components and their assembly, until the final phase, including mechanical installation and pre-shipment tests of ready equipment. The guests had therefore a possibility to visit not only the Commercial and After Sales Departments, which they have everyday contact with, but also the Designing Department or Automation Engineers, responsible for Software. Moreover, they could see the daily work in Ice Group’s production rooms. The stay at Ice Group ended with a common meal prepared both for the invited guests and the company employees and in the evening, there was an official dinner party for the guests.

“The cooperation between the Supplier and the Buyer in relation to the construction of industrial ice cream machines is based first and foremost on trust, which I regard as absolutely indispensable in this relation” – this exceptionally accurate statement of the jubilarian, the 50-year-old with 25 years of experience in the ice cream business – Mariusz Goik – constitutes an excellent punchline to the meaning of the meetings on 8th and 9th December.

We hope that, as Ice Group, we not only haven’t let the trust of our Clients down in the last 25 years, but strengthened it, thanks to the increasing quality of our machines, constantly widening the production program and the growing number of Clients, as well as such events as Open Days in our seat.