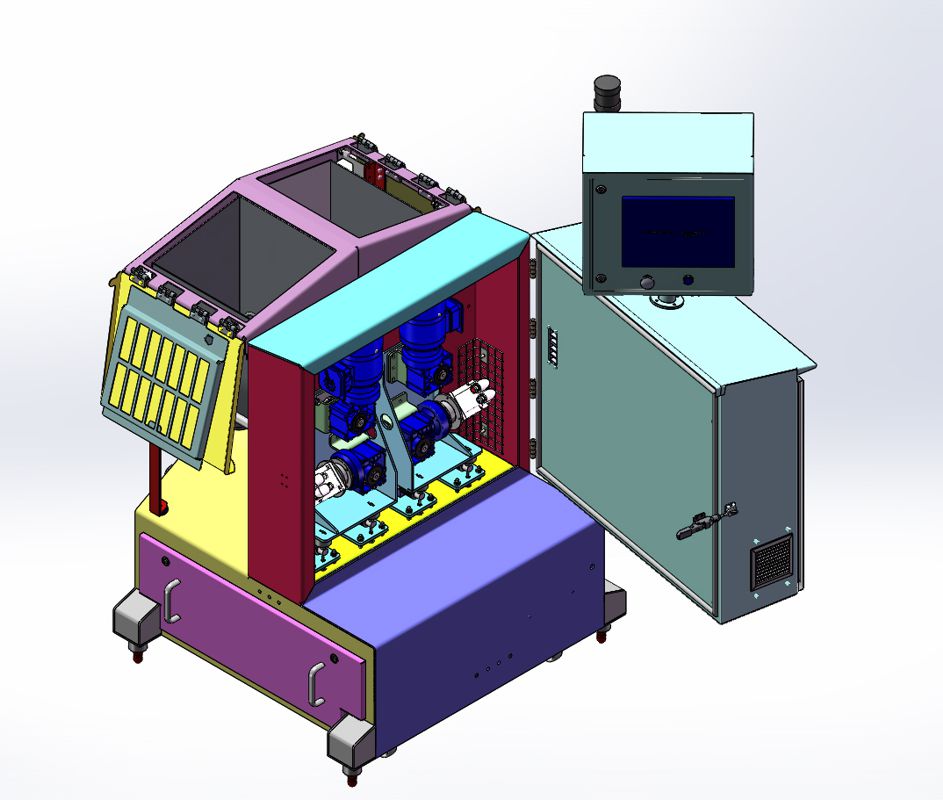

The Municipal Office of Rybnik started the initiative of bringing interest in production companies among the school youth. Therefore they contacted us in order to organize visits of two classes from the Primary School no 13 and from the Primary School and Nursery Unit no 3 in Rybnik. The young people could see the way production process of ice cream manufacturing line is organized. The visits boosted children’s knowledge about the types of work and workplaces, and we hope that children themselves were able to widen their scope of plans for their further education. It was a real pleasure to host You. We await next such initiatives of the Municipal Office.

Wizyta uczniów szkoły podstawowej

Urząd Miasta Rybnik wyszedł z inicjatywą zainteresowania młodzieży szkolnej miejscowymi zakładami pracy w związku z czym skontaktował się z nami w celu organizacji wizyt dwóch klas. Szkoły Podstawowej nr 13 i Zespołu Szkolno-Przedszkolnego nr 3 w Rybniku. Młodzież odwiedziła nas w dniach 05 i 06 luty 2019r. Uczniowie mogli zobaczyć jak przebiega proces produkcji linii technologicznych do wytwarzania lodów. Wizyty w znacznej mierze przyczyniły się do zwiększenia wiedzy o rodzajach i miejscach pracy, a same dzieci, mamy nadzieję, mogły poszerzyć plany na swoją dalszą edukację. Było nam bardzo miło Was gościć. Czekamy na kolejne takie inicjatywy ze strony Urzędu Miasta.