Rybnik Lunar Half Marathon

2021-06-26

2021-06-26

2021-04-28

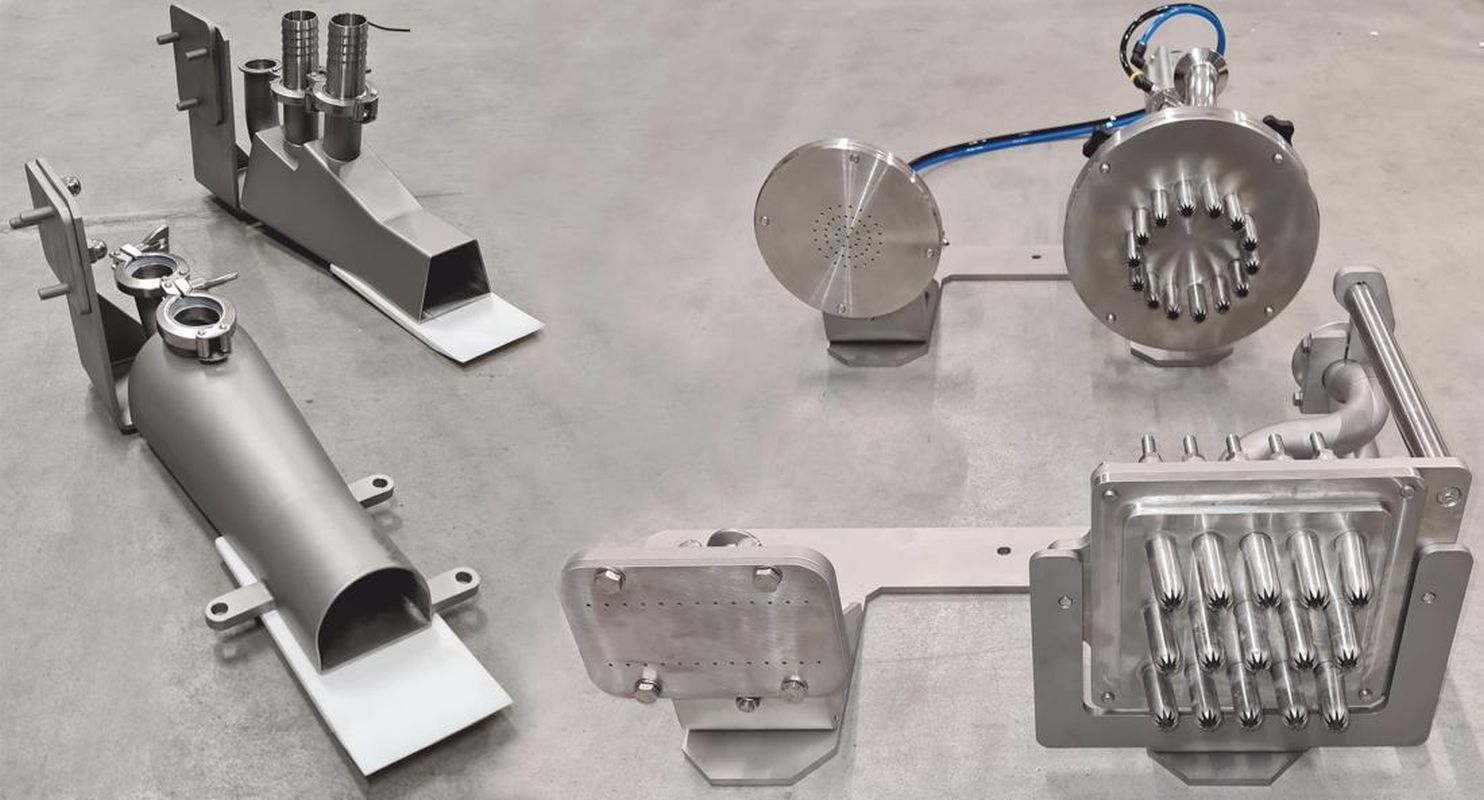

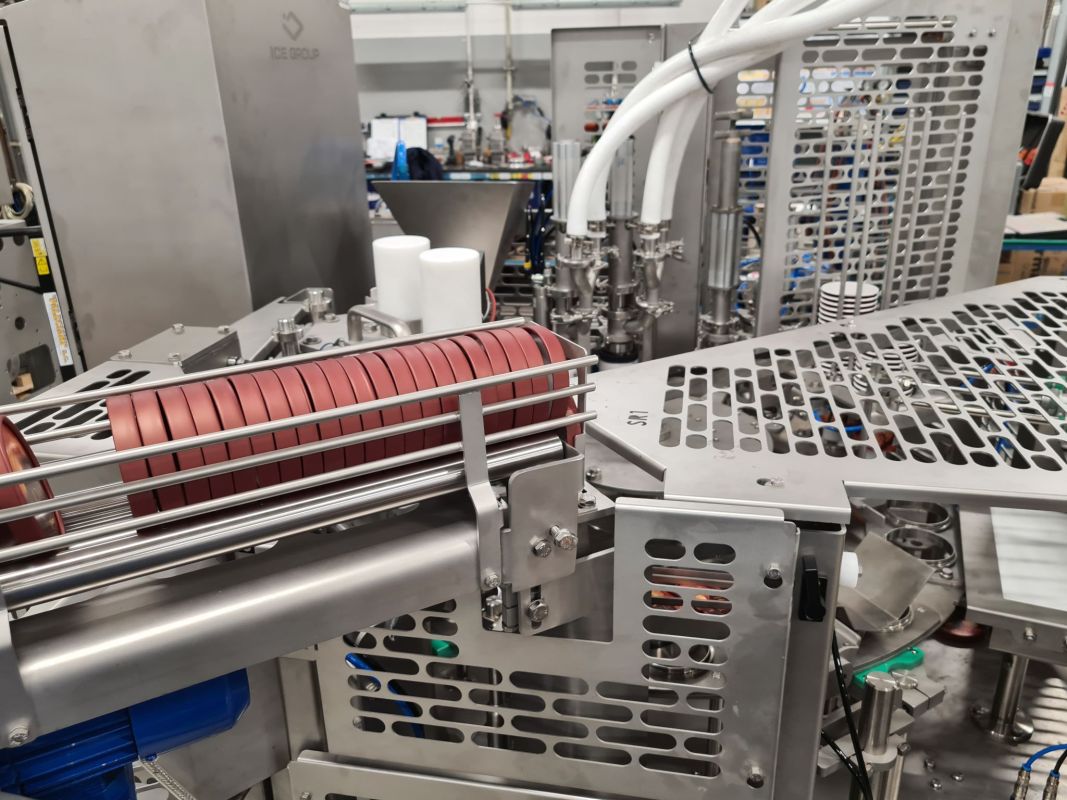

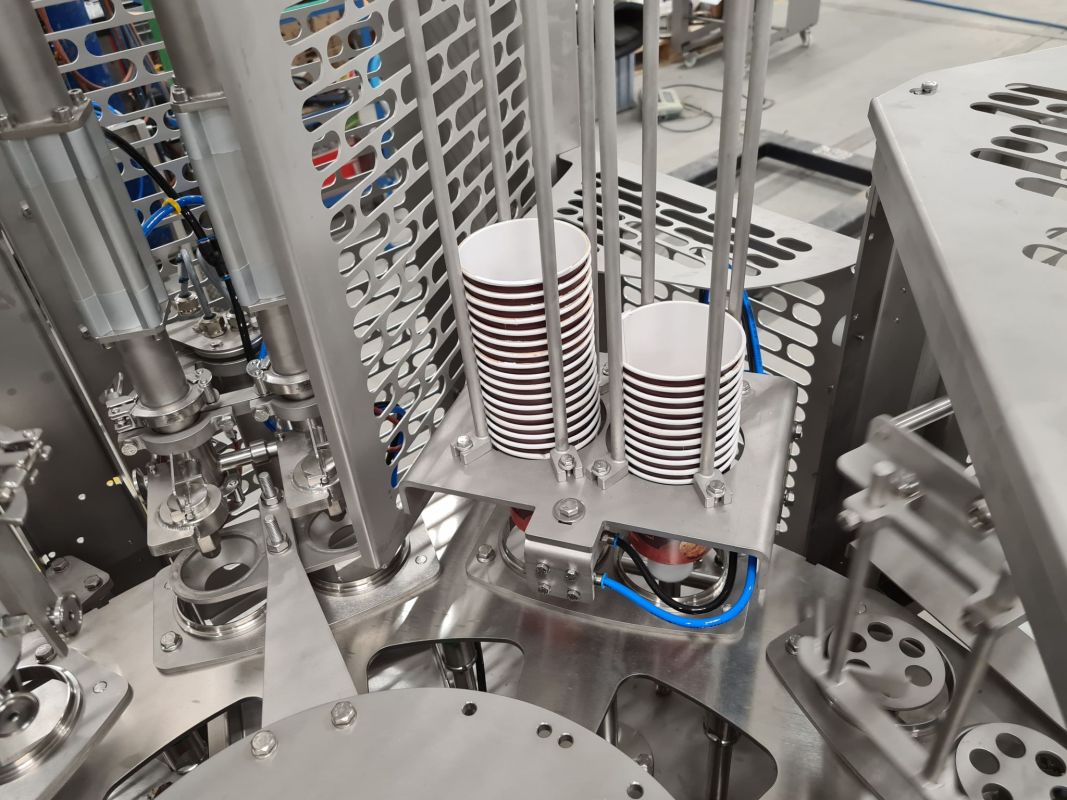

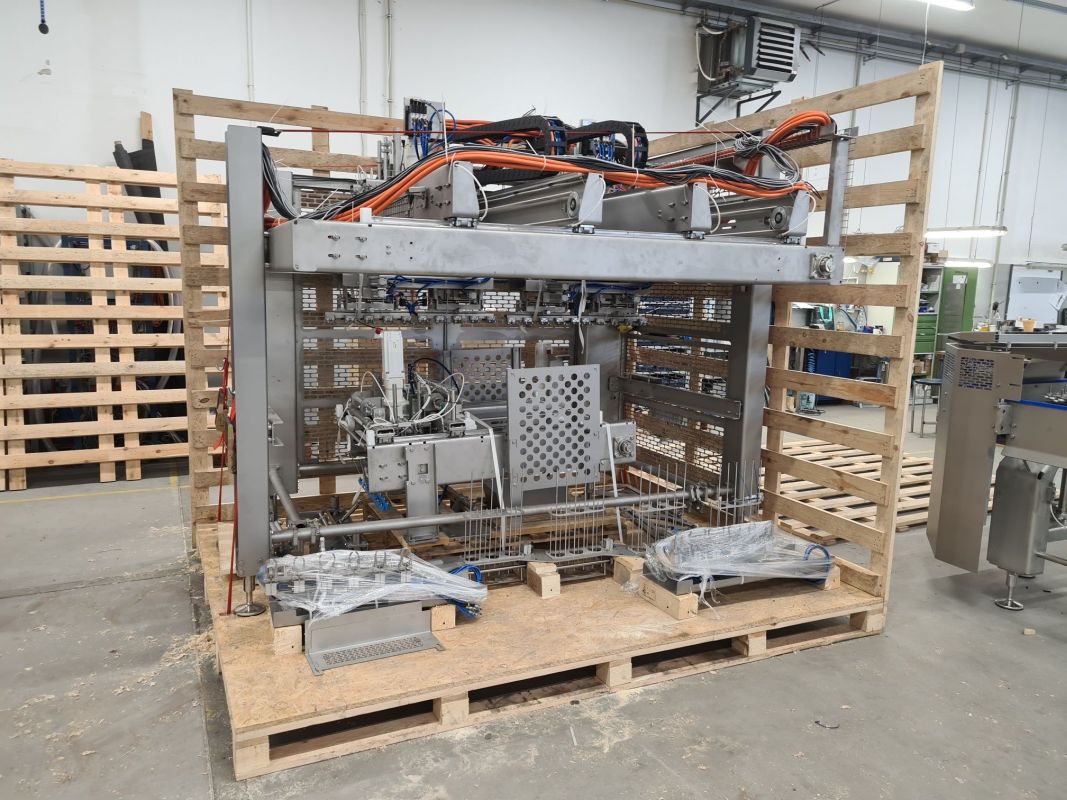

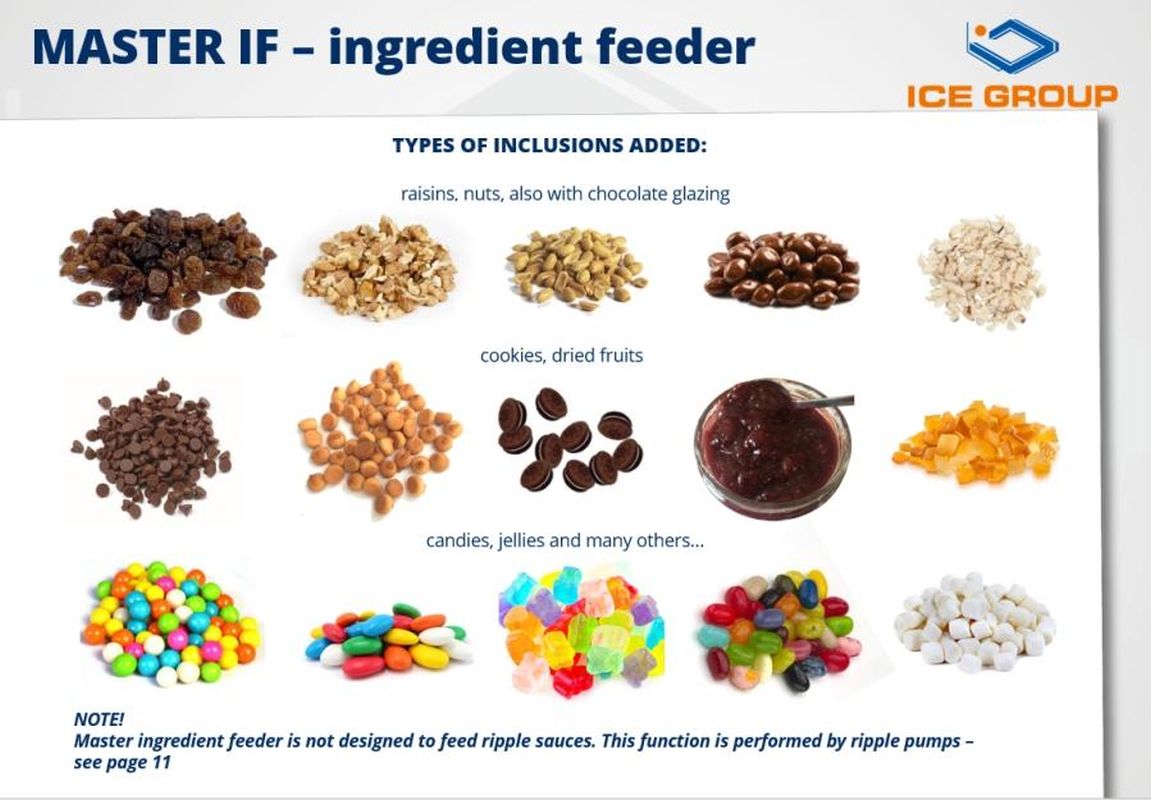

Todays shipmen: set of machines EXPERT CRF 2 rotary filling machine for cups ( 150ml-500 ml with sealed lid and snap on lid ) and cones . Capacity range 3000-6000 cups per hour , MASTER IF 3000 ingredient and fruit feeder, SYRUP PUMP with hopper .

Destination : Caucasus country.

2021-04-20

Todays shipment : Master FF - fruit and ingredient feeder with additionally heated hopper with circulation pump for : "straciatella effect ''. Destination : Asia.

2021-04-09

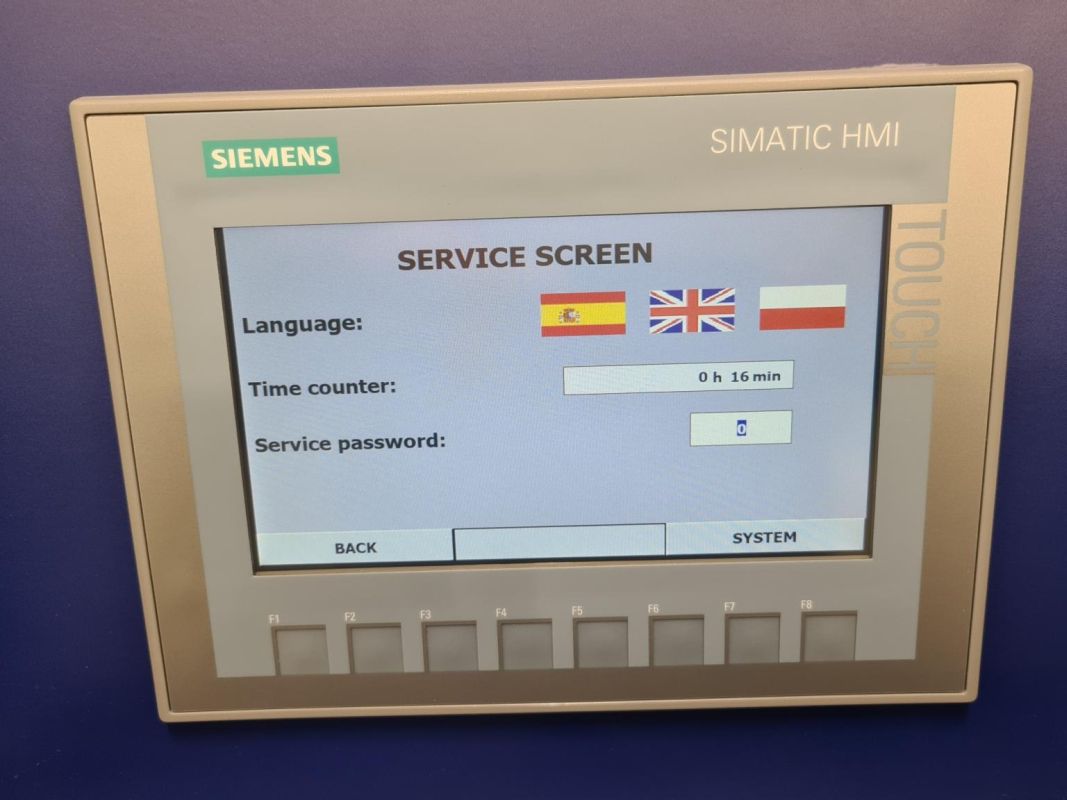

Todays shipment Master IF 4000 , destination West Europe. High end machine , redesigned high higenical construction with isolated double wall main hopper , 10 " HMI full colour touch screen Allen Bradley , inteligent and economical tensometric loss-in-weigh system , special construction auger .

2021-03-01

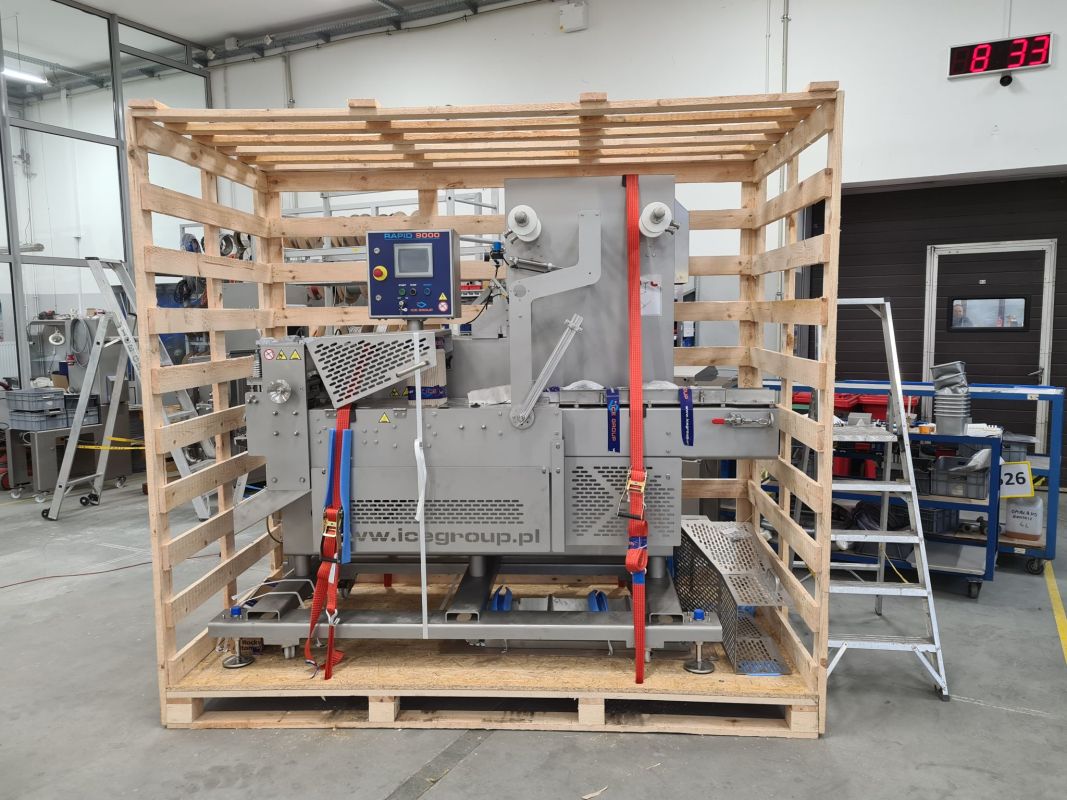

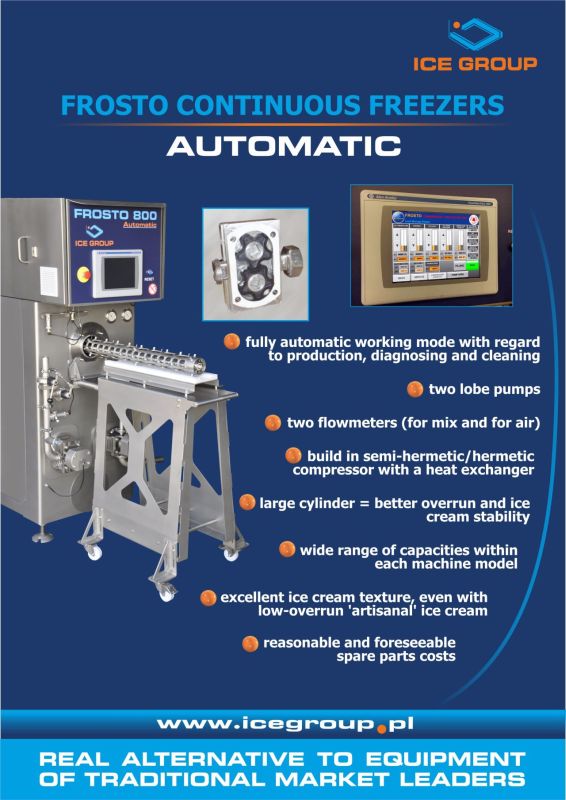

Another week with a lot o shipments . Igloline 12000 hardenning / production line for wafer cups and cones for russian Customer . Automatic destacking station for wafer cups, follow-up dosing sections , two continuous freezers FROSTO 1600 and two flow-wrappers RAPID 9000. Automatic transfer systems , unloading from trays and many more...

2021-02-12

Two continuous freezers FROSTO 1600, self contained, on our testing station before shipment. Capacity 1600 liters of ready ice cream per hour.

Destination : Eastern Europe .

2021-01-18

Jumbo Servo Double - semi automatic filling station with up and down movment controlled by PLC , capable of lifting up heavy, multi-outlet dosing systems along with ice cream collectors and flexible piping full of ice cream, while the station is working.

Destination : Africa .

2021-01-15

Last control before shipment : Master FF - ingredient feeder, high end unit with tensometric lost-in-weight system touch screen panel and many more ... Destination : Western Europe.

2021-01-07

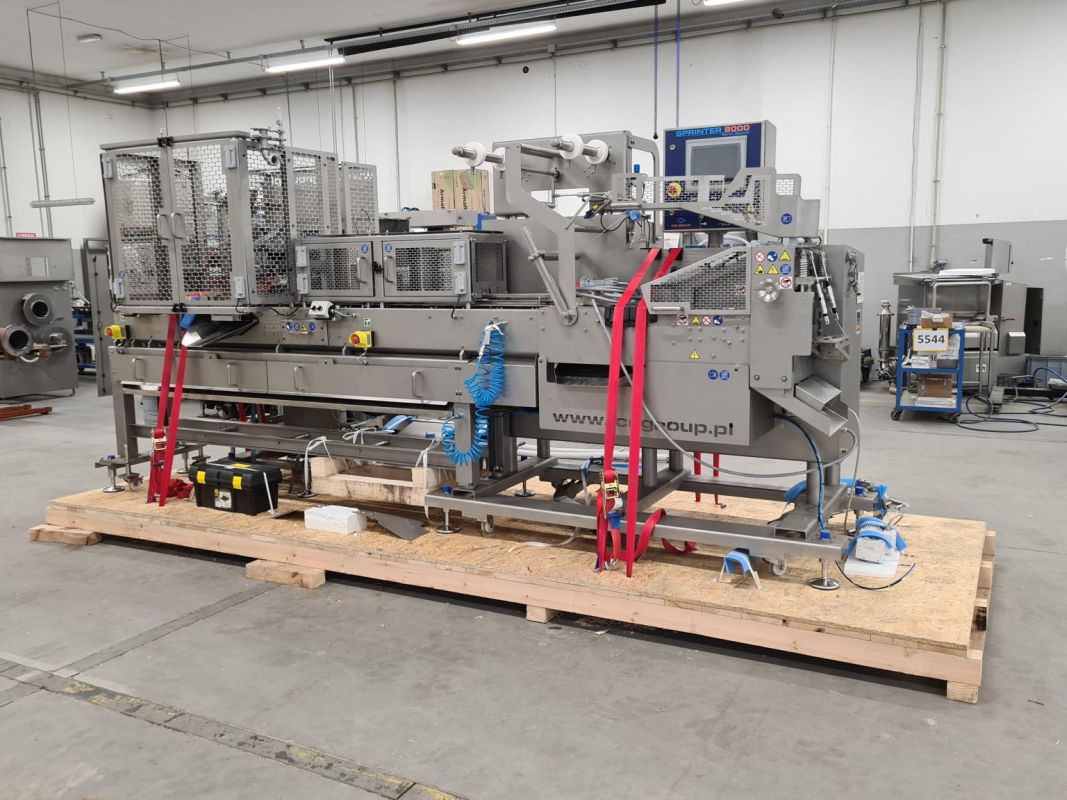

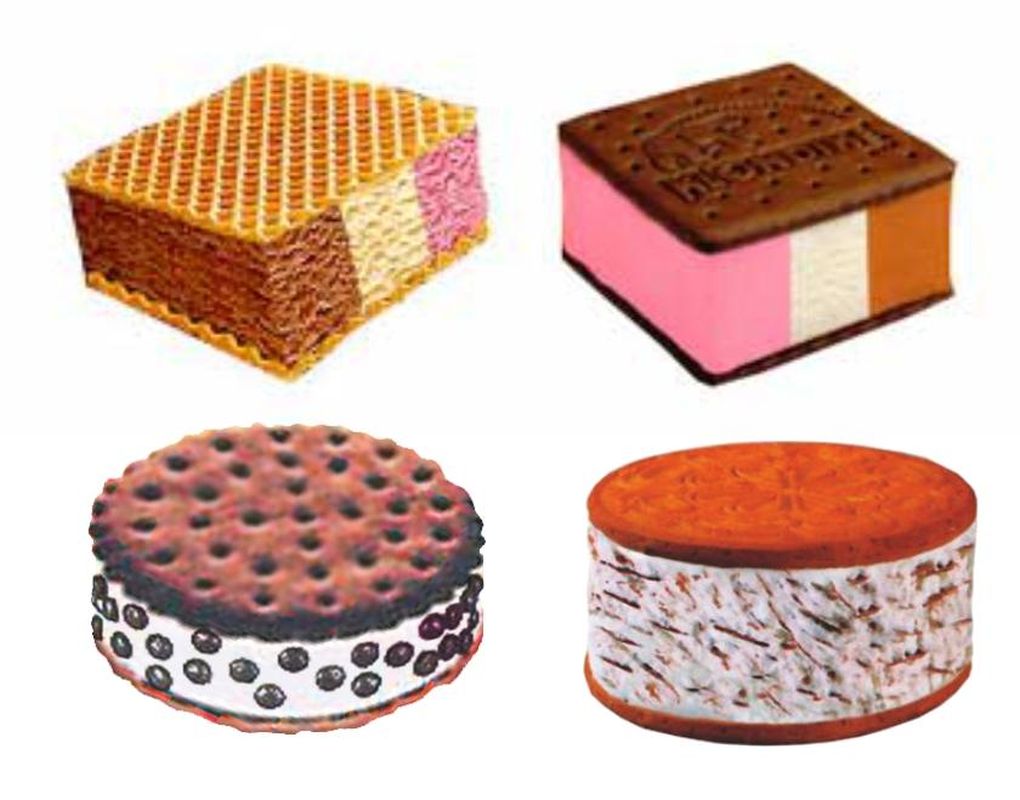

First delivery in 2021: automatic sandwich machine SPRINTER 8000 SPECIAL for round "country '' type sandwich. Equipped with an independent ( servo driven ) extruding and cutting station and prepared for interchangeably dosing station in the future. Destination : Western Europe .

2020-12-28

Last shipment in 2020 , automatic extruding tray tunnel IGLOLINE 1000 , special model for ice cream cakes ( round and rectangular) logs ( swiss rolls ) and similar products. Highly customised and very flexible. Destination : Asia